Drilled shafts are high-capacity deep foundation systems, also known as drilled piers, caissons, bored piles, or cast-in-drilled-hole piles (CIDH).

Common uses

Process

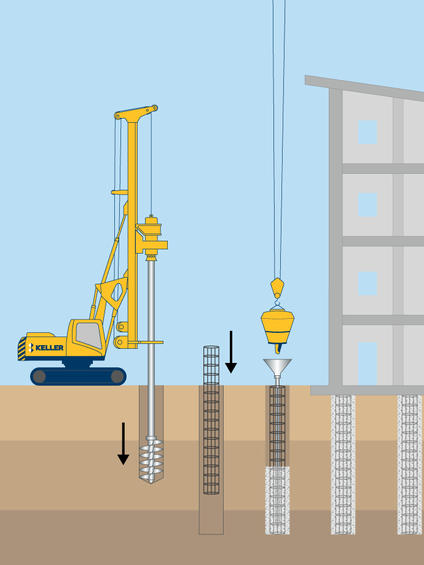

Drilled shafts for structural support can be installed by the dry (open hole), stabilizing polymer slurry, or steel-cased methods. The permanent casing is typically only specified in corrosive environments, voided (open cavity) conditions, or for shafts drilled through the water. The temporary casing may also be required for open-hole shaft installation if adverse subsurface conditions are present (i.e., groundwater, caving soils, granular soils, sidewall loss, etc).

A hole of the required diameter is augered to the required bearing stratum or design depth, cleaned out, and inspected. Inspection may be manual for shallow holes or with a Mini-SID (shaft inspection device) or down-hole camera. Large boulders encountered during auguring may prevent shaft continuity or required bearing capacity and must be removed, typically by drilling. A core barrel or rooting tool may also be used. If reinforcement is required and the client elects to remove this from their scope, Keller will purchase and fabricate the cage(s) on-site. Following insertion of the steel cage, concrete is placed either by freefall or tremie methods. The casing, if temporary, is then withdrawn. The completed shaft can resist compressive and lateral loads and uplift forces.

Access conditions required for drilled shaft construction are as variable as the diameters and depths to which they can be drilled. Drilled shafts can be constructed in low headroom and limited access and effectively support most structures, including buildings, tanks, towers, and bridges. Keller owns and maintains a diverse and up-to-date drilled shaft equipment fleet outfitted with the highest quality, state-of-the-art tooling. Experience combined with specialty proprietary drilling equipment and tooling allows Keller to meet specific site constraints such as limited access and low overhead construction. For various subsurface and access conditions, drilled shafts may be the answer for your project.

Advantages

Quality assurance

Non-destructive test methods help determine the quality of the concrete throughout the length of the shafts. Crosshole sonic logging (CSL) and/or Gamma-Gamma logging (GGL) can be conducted by placing test pipes in the shaft reinforcement and subsequently testing the integrity of the pile concrete.

Load testing can be conducted on drilled shaft foundations to verify the load-carrying capacity of the foundation elements and/or the quality of the subsurface materials. This testing can be completed on production or sacrificial drilled shafts. Load testing is often completed by one of the following methods: Osterberg Cell (O-Cell), direct static testing, and statnamic testing for both compressive and lateral testing. Testing is often utilized to refine designs and can result in significant savings to projects by removing some of the uncertainties inherent in the typical foundation design process.